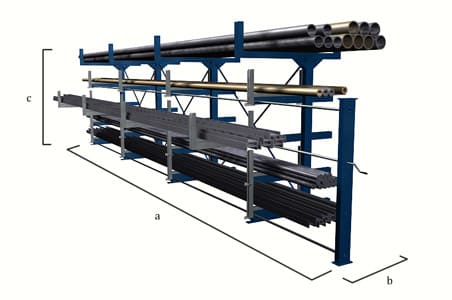

ROLL OUT CANTILEVER RACK

Efficient storage and transport of steel profiles, aluminum, stainless pipes or flat iron by moving them outside the rack

Compact storage of aluminum profiles, stainless steel, hollow sections, iron angels, etc. in rolling out drawers

This roll out cantilever rack is suitable for the compact storage of long profiles. Pipes, bars, hollow sections, flat iron, strips, … are stored in an orderly manner. The arms can be completely extended with a crank which guarantees a complete and full access to each profile. Since the handling is done in only one movement and since the open drawer is located outside the rack, this kind of rack is the solution for a safe and quick storage of your profiles.

In this roll-out cantilever rack you can store profiles of 3, 6, 12, 15 or even 20 meters. The client chooses the number of drawers, the depth and the loading capacity per drawer. The individual height per drawer can also be determined by the customer. In other words, the particularies of the roll-out cantilever rack are completely adjusted to the needs of the customer.

Video: Transport of steel profiles, pipes and flat iron with a crane from the roll-out cantilever rack

With little effort the drawer is brought outside the rack by using a handle. Thanks to the drawers which are 100% extendable, you have full access to each profile. Therefore it's an easy system for loading or unloading long materials.

Would you prefer to extract the drawers manually instead of using a handle? Take a look at our storage of profiles with extractable drawers.

Steel profiles, easy to load and unload with the loading crane thanks to the 100% extendable drawers

Each extractable drawer is completely accessible outside the rack which allows quick and easy loading or unloading of all sorts of profiles.

Roll out cantilever rack - Handling

Use of the cantilever roll-out rack for the storage of steel and stainless steel profiles, bars, strips hollow sections, …

This type of roll out cantilever rack is suitable for the compact storage of all kind of long profiles. Pipes, bars, strips, tubes, hollow sections, flat iron, … are stored in a synoptic manner.

100% rolling out drawers = 100% available profiles, tubes, pipes, hollow sections, bars, …

The roll-out cantilever rack is very user-friendly.. Only 1 person is needed to execute the handling. With a handle the operator can easily open the drawer. This task requires little energy, effort and time, even in the case of a heavy load. Thanks to the 100% extendable drawers, you have full access to each long profile. When the drawer is rolled out, you can easily lift your profiles, pipes and bars with a loading crane.

Since you perform the handling in only one motion and since the opened drawer is outside the rack, this is a safe and easy solution for storing your pack of long iron materials.

Long profiles

Lengths of 3 - 6 - 12 - 15 - 20 m

Supporting arms

Roll out 100%

Loading with a crane

Safe and easy

Loading capacity

Per drawer: determined by client

Video 1

Video 2

Video 3

Video 4

Video 5

Video 6

Video 7

Video 8

Video 9

Video 10

Video 11

Video 12

Video 13

Video 14

Video 15

Video 16

The customer chooses the number of drawers and the loading capacity, depth and height of the drawers. For more information, please contact us.

For deliveries in the UK, please visit our english website Eurostorage Systems.